Formal Visual Inspection

Formal visual inspections should only be carried out by persons competent to do so; if someone is not competent they could miss something really important. The formal visual inspection is arguably the most important part of the portable appliance testing process.

When PAT testing is done the visual inspection must be carried out before any tests using a PAT machine.

The results of the inspection must be documented.

The following must be considered when carrying out the inspection:

Suitability of the equipment/environment

The equipment should be assessed for its suitability for the environment or the nature of the work being undertaken. When the work environment is harsh or hazardous particular care needs to be taken when selecting the equipment and assessing the frequency of inspection and testing.

A check should be made to ensure the equipment is installed and is being operated in accordance with the manufacturers instructions. Notwithstanding the manufacturers instructions the following are examples of items which should be checked:

- Cables located correctly so as to avoid damage

- Means of disconnection/isolation readily accessible

- Adequate equipment ventilation

- Equipment positioned to avoid strain on the cable

- Equipment operated with the covers in place and any doors are closed

- Indiscriminate use of multi-way adaptors and trailing sockets is avoided; daisy-chain

- No unprotected cables run under carpets

Disconnection of equipment

The means of isolation from the electricity supply must be readily accessible to the user, i.e. in normal circumstances it must be possible to reach the plug and socket without to much difficulty.

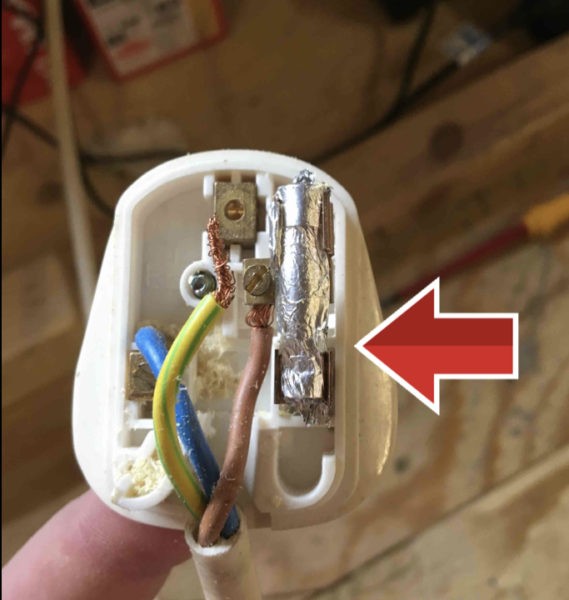

The condition of the equipment

Prior to the commencement of the users should be asked if they are aware of any faults and if the equipment works correctly. The following items need to be inspected:

- The flexible cable; for any tears or abrasions

- The appliance casing; is it secure, not damaged in any way

- The plug head; inside and out

The following are checks that should be carried out as part of the above, where possible:

- Check detachable power cords to Class 1 equipment incorporates a CPC

- Identify signs of overheating

- Internal inspection; cord security, polarity, connections

- If non-rewirable plug; cord security, burning odours

- Correct size fuse fitted, BS marked, ASTA marked

- Security of plug cover

- Check the flexible cable connections and anchorage at the equipment, if practical